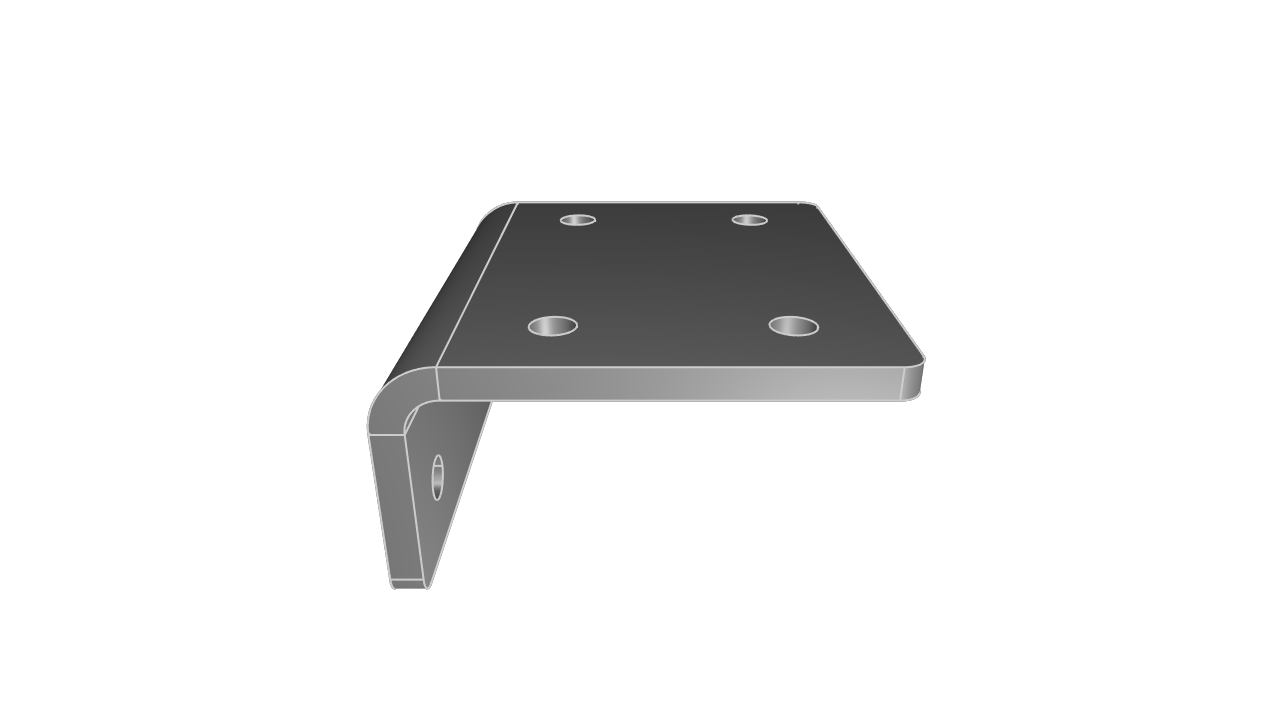

bracket

ManufacturingAutomotiveAerospaceConstruction

This is a bracket that holds a shelf. It is made of aluminum and is designed to hold a force of 300 lbs. The bracket is 6 inches wide and the force is applied at the end of the shelf, 12 inches from the wall. The bracket has a factor of safety of 1.2. The legs of the bracket are 5 inches and 2 inches long. The thickness of the bracket is calculated from the constraints provided.

KCL